Seal the Deal is intended to be an informative and educational publication for ChemMasters’ network of independent manufacturer’s representatives, distributors and contractors. We don’t want to make you chemical engineers, but we do want to help you feel better informed and more comfortable discussing construction chemicals. If there are specific products or topics you would like to see addressed in a future issue, please contact

John Fauth.

Maintaining Decorative Concrete Sealers

Beauty is in the eye of the beholder… the origin of this phrase traces its roots back to ancient Greece, but they might just as well have been talking about modern stamped concrete. Once that elusive beauty is captured, the trick is to properly maintain your stamped concrete so it

remains sound and looks good for many years to come.

There are many contaminants that can stain concrete or acrylic sealers. Some of the common sources include:

- Decaying leaves that produce tannic acid

- Fertilizers & lawn chemicals

- Rust & oxidation from furniture, buildings, roofs, etc.

- Food & beverage spills

- Grease & oil spills

- Automotive chemicals

Your concrete sealer is durable, resilient and attractive, but it requires some basic maintenance and care in order to look good throughout its serviceable life. Some suggestions include:

- Clean drips and spills as soon as they occur.

- Use a mild detergent if necessary. Don’t use cleaners/degreasers with harsh solvents, as they will damage the sealer.

- Place drip/spill barriers below and in front of grills and other stationary sources of stains.

- Re-paint rusting patio furniture, planters, etc.

- Replace/repair leaky gutters & downspouts that may be sources of oxidized metals, or roofing materials.

- Routinely rinse off your concrete.

- Do not allow mowers, lawn equipment or other potential sources of leaks and drips to dwell on decorative concrete.

If you’re sealer is looking a little worn, don’t jump to the conclusion that it needs to be removed. Strippers contain harsh chemicals that pose a health risk, are harmful to lawns and landscaping, and produce residue that can’t be hosed down the drain. As a result, stripping or

removal of a concrete sealer should be a last resort.

There is a common misperception that when a decorative sealer loses its gloss, it has also worn away. But decorative sealers can lose their gloss long before they lose the ability to protect your concrete from stains, freeze/thaw cycles, and other means of damage. As a result,

concrete sealers are often applied with greater frequency than necessary and tend to “build up”. Over time, this build up can cause problems of its own, including:

- Loss of “breathability”, resulting in whitening or delamination.

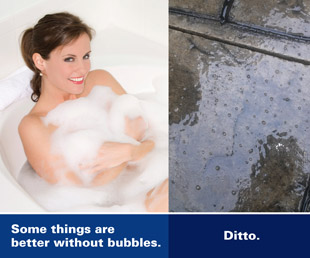

- Bubble formation as solvent is trapped at greater coating depth.

- A “gummy” or incomplete cure from trapped solvent.

- Bubble formation from entrapped air.

If your solvent-based sealer has bubbled or exhibits signs of whitening and delamination, the best advice is to repair the coating rather than remove it. These lacquer systems can frequently be repaired with careful use of xylene (or xylol).

- Power wash the sealer and allow to dry overnight.

- Lightly saturate a small area with xylene and allow to dwell on the sealer for two minutes. This re-solvates the sealer.

- Gently back roll with a solvent resistant roller cover to break any bubbles or remove whitening/delamination.

- Repeat the process in small areas until the entire area has been repaired.

- Allow the solvent to evaporate and the sealer to cure on the concrete surface.

This process will solve most of the common sealer issues. Some localized spots may require more than one treatment.

Eventually, UV sunlight damages acrylic sealers in the same way it damages your skin. Prolonged UV exposure causes sealers to develop micro-cracks and pitting that detract from gloss. In many cases there is sufficient sealer remaining on the surface, but it needs a little help to

regain its original aesthetic qualities. If that’s the case with your decorative concrete, don’t re-seal it… restore it with Gloss Restorer SRT.

Gloss Restorer SRT will chemically alter dull, weathered concrete sealers to restore their original gloss and finish, without bubbling or substantially increasing the coating thickness. No bubbles, no whitening, no delamination… no problem!

If it’s been several years since your decorative concrete has been sealed, you might require a full reseal. When resealing, follow a few simple suggestions:

- Fully read and understand the Product Data Sheet for any sealer you intend to use. All ChemMasters Product Data Sheets and Safety Data Sheets are available here.

- Plan your project for a few days of dry weather.

- Power wash your decorative concrete to remove dirt, tree sap, pollen, etc. along with any poorly bonded sealer. Be careful not to etch the concrete surface.

- Allow the concrete to dry out overnight.

- Most sealers may be spray applied (with solvent resistant sprayers similar to the Chapin Extreme) or roller applied (with solvent resistant roller covers).

- Apply according to the directions as they appear on the Product Data Sheet. Carefully adhere to the recommended application rate… more is not better!

- Allow the sealer to fully cure according to the Product Data Sheet.

Helpful Hint: If you’re not sure whether there is any sealer remaining on your concrete, pour a little household vinegar on an inconspicuous area. If it bubbles/foams there’s no sealer.

Canada and many US states have enacted restrictive VOC (Volatile Organic Compound) limitations (see

What are VOC’s?) which limit the solvent content of many decorative concrete sealers. These low-VOC products

are often less user friendly, more prone to bubbling, over application, stringing, cob webbing, etc. If you’re in a low-VOC state, consider the use of ChemMasters Polyseal EZ.

If your sealer is beyond repair and removal is the only option, consult ChemMasters Technical Department for removal instructions.

Seal the Deal is intended to be an informative and educational publication for ChemMasters’ network of independent manufacturer’s representatives, distributors and contractors. We don’t want to make you chemical engineers, but we do want to help you feel better informed and more comfortable discussing construction chemicals. If there are specific products or topics you would like to see addressed in a future issue, please contact

John Fauth.

Seal the Deal

Seal the Deal